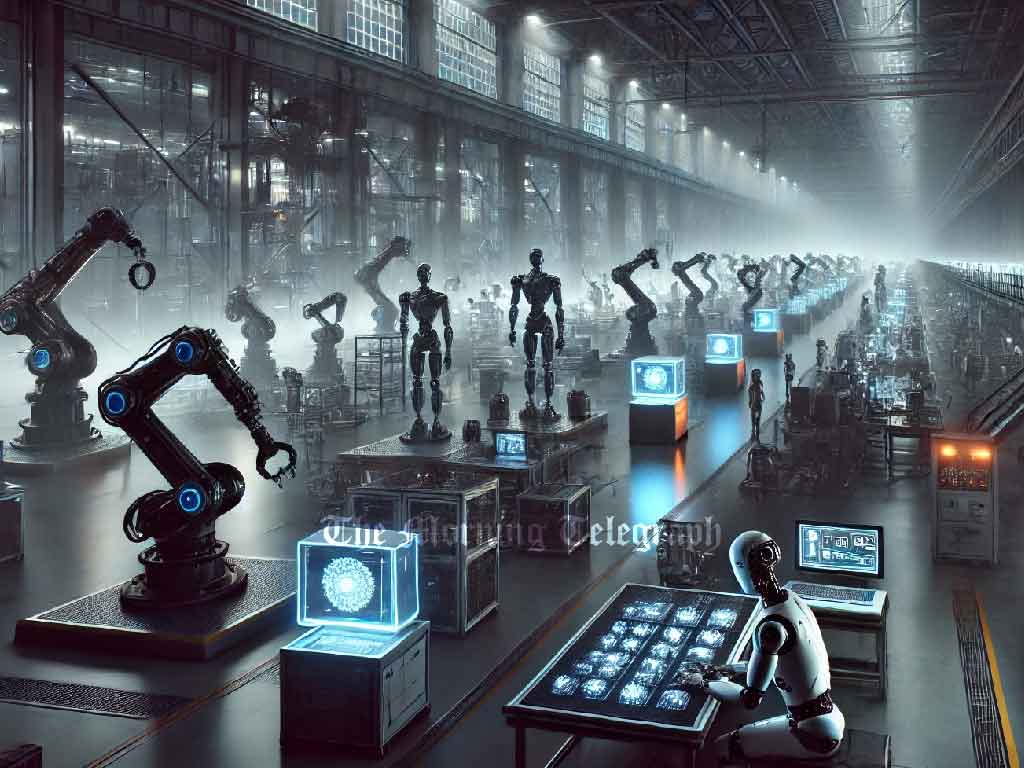

The manufacturing industry is undergoing a profound transformation, driven by advancements in artificial intelligence, automation, the Internet of Things, and data analytics. A major development in this shift is the emergence of fully autonomous “dark factories,” which operate continuously without human intervention. These high-tech facilities maximize efficiency, precision, and output while functioning without lighting, reducing operational costs.

Dark factories rely entirely on automation, eliminating the need for on-site human workers. They integrate AI-driven robotics, interconnected IoT systems, and sophisticated automation protocols to ensure seamless operations. Without the necessity of human presence, these factories significantly cut down on energy consumption while maintaining consistent, high-quality production standards.

Automation in dark factories covers the entire production process, from material handling and assembly to packaging and quality control. Artificial intelligence and robotics work together to minimize errors, accelerate production, and maintain superior precision. IoT connectivity allows machines to communicate in real time, making autonomous adjustments and predicting maintenance needs. This real-time adaptation enhances operational efficiency and reduces downtime.

Machine learning algorithms play a key role in maintaining high standards by continuously monitoring for defects and inconsistencies. This AI-powered quality assurance process not only improves product reliability but also reduces material waste. In industries such as electronics and pharmaceuticals, where contamination-free environments are critical, dark factories utilize autonomous air purification and dust-removal systems to maintain sterile conditions without human intervention.

One of the defining advantages of these factories is their ability to sustain high-speed and scalable production. Automation enables rapid assembly, with some facilities capable of producing units within seconds. The scalability of dark factories allows manufacturers to meet rising demand without compromising quality. Additionally, these facilities optimize energy consumption by dynamically adjusting power use based on production needs, reducing operational costs and promoting sustainable manufacturing practices.

The expansion of dark factories is being driven by substantial investments in automation and artificial intelligence. Companies across the globe are allocating billions toward developing these next-generation production hubs, recognizing their ability to enhance efficiency, lower costs, and maintain superior quality. Many of these factories now span vast areas and are responsible for manufacturing high-tech products, including consumer electronics, automobiles, and pharmaceuticals.

The rise of dark factories represents the next stage in industrial automation, building upon previous advances in robotic production lines, AI-driven analytics, and real-time monitoring. Fully autonomous factories are redefining the way products are manufactured, delivering unparalleled speed, efficiency, and consistency.

The shift toward fully autonomous manufacturing will have significant implications. Continuous 24/7 operation will greatly increase production output. AI-driven real-time monitoring will enhance quality control by minimizing defects. Automated energy management will contribute to environmentally sustainable manufacturing. The workforce landscape will also shift, with a reduced demand for manual labor but an increased need for professionals skilled in AI, robotics, and data science. Companies that adopt smart manufacturing will gain a competitive advantage, positioning themselves at the forefront of industrial innovation.

Dark factories are no longer a vision of the future; they are actively reshaping the manufacturing landscape. By harnessing artificial intelligence, IoT, and automation, companies are unlocking unprecedented levels of efficiency, scalability, and sustainability. As technology advances, fully autonomous factories will become the new industry standard, revolutionizing global production and setting the stage for a future where precision, speed, and sustainability define manufacturing success.